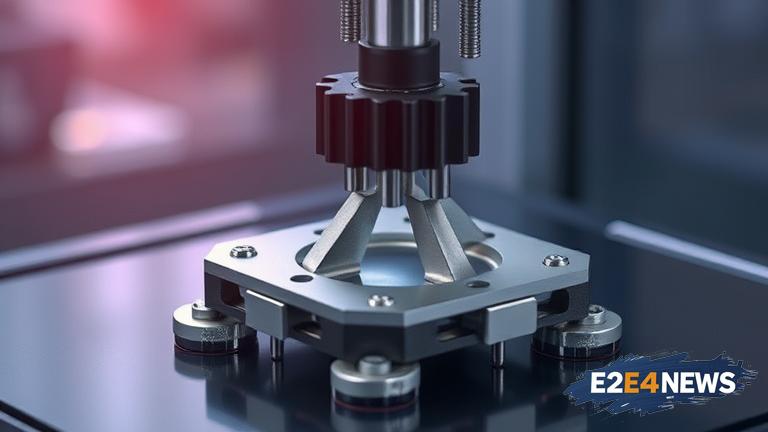

In a groundbreaking study, a team of researchers has successfully developed a novel 3D printing technique that enables the creation of intricate metal structures with unparalleled precision and accuracy. This innovative method has the potential to revolutionize various industries, including aerospace, automotive, and healthcare. The researchers utilized a combination of advanced materials and sophisticated printing technologies to achieve this breakthrough. By leveraging the unique properties of metal alloys, they were able to create complex structures with tailored mechanical properties. The new method involves the use of a specialized 3D printing system that can precisely control the deposition of metal particles. This allows for the creation of structures with complex geometries and internal architectures. The researchers demonstrated the capabilities of their technique by printing a range of complex metal structures, including lattice networks and porous materials. These structures exhibited exceptional mechanical properties, including high strength, toughness, and resistance to fatigue. The breakthrough has significant implications for various fields, including aerospace engineering, where complex metal structures are used in aircraft and spacecraft components. The automotive industry is also expected to benefit from this technology, as it can be used to create lightweight and high-performance vehicle components. Additionally, the healthcare sector may utilize this technique to develop customized implants and surgical instruments. The researchers believe that their method can be scaled up for industrial applications, enabling the mass production of complex metal structures. This could lead to significant reductions in production costs and times, making it an attractive option for manufacturers. The study’s findings have been published in a prestigious scientific journal, highlighting the significance of this breakthrough. The researchers are now working to further refine their technique, exploring new materials and applications. As the technology continues to evolve, it is expected to have a profound impact on various industries, enabling the creation of complex metal structures with unprecedented precision and accuracy. The development of this new 3D printing method is a testament to the power of innovative research and its potential to transform industries. With its potential to revolutionize manufacturing, this breakthrough is poised to make a significant impact on the global economy. The researchers’ work has been recognized internationally, with experts hailing it as a major breakthrough in the field of 3D printing. As the technology continues to advance, it is likely to attract significant investment and attention from industry leaders. The potential applications of this technology are vast, and it is expected to play a major role in shaping the future of manufacturing. With its ability to create complex metal structures with unprecedented precision and accuracy, this breakthrough has the potential to transform industries and revolutionize the way we manufacture complex components.